Bearings Design

Plastic High Temperature Bearings - BHT Series

Most commercial plastic and metallic and bearings have operating temperature ranges of approximately 200 F. In the 300 F to 500 F range exotic seals, greases, bearing fits, clearances and housings are required. It is possible to eliminate many of the associated purchasing, installation and maintenance costs associated with these applications by utilizing MIC's BHT series bearings, especially in the case of bearing inserts (PI-BHT). Requiring no lubrication, retro-fitting of existing housings and having operation temperature ranges to 600 F, these bearing products are the economical, simple answers to problem applications in the bakery, paving and processing industries. Utilizing the same dimensional and engineering data of MIC's other bearing products, the BHT series is available in a variety of bore ranges to fit many application. Machined from pure . virgin high temperature material , these products are new technology solutions to age old industry problems.

Determining Approximate Bearing Loads

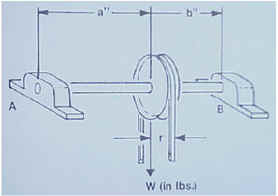

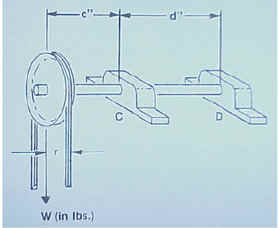

The placement of a drive system in relation to the bearing supporting it can have a significant impact on the life of those bearings. The more evenly a load is distributed over a bearing set, the longer the set will last. Formulas for determining bearing loads are as follows:

|

|

|

|

- r = Radius (1/2 of O.D. of pulley or sprocket)

- W = Weight of shafting, sprocket, pulley, chain or belt pull, etc.

Equations for Determining Bearing Loads

|

When torque is in INCH-LBS |

|

When torque is in FT-LBS |

|

When horsepower is known |

- L = Total shaft load on bearings (LBS)

- N = Revolutions per minute

- r = Radius at which load acts (INCHES)

- T = Torque (INCH-LBS or FT-LBS) (see below)

- f = 'f' factor from Drive Factor Table (see Drive Factor Table below)

Determining Drive Factor

Drive Factor Table ('f')

| Type of Drive | 'f' factor |

| Chain | 1.0 |

| Flat-belt (180° wrap) | 2.5 |

| Flat-belt (less than 180° wrap) | 3.0 |

| V-belt | 2.0 |

| Wire rope (45° grooved pulley) | 2.0 |

| Wire rope (60° grooved pulley) | 3.0 |

After approximate load has been determined (from known data or by using the above formulas), PV value can be calculated.

Determining PV Value

The operating PV of a bearing is actually a measure of temperature. The maximum allowable PV for any situation will vary depending on the thermal and mechanical characteristics of the material selected for the bearing. Because of this, the ambient air temperature of the environment and the corresponding housing temperature is important.

Since heat is the major factor in determining the life of a bearing, the ability to dissipate heat through the shaft with a lubricant or by operation in a spray or bath will reduce bearing failure rate, or increase bearing life.

Another factor in reducing the life of any bearing is chemical action on a material not suited for such an environment. Any abrasives introduced to a bearing will wear away the bearing material and significantly reduce its life. Most plastic materials will absorb some particles of an abrasive to a much greater degree than a metal bearing and therefore reduce the damage done to both the shaft and the bearing, but it will not totally eliminate that wear.

Equations for Determining PV Value

- A = D I

- P = L / A

- V = (.262) D RPM

- PV = P V

- P = bearing load (PSI)

- A = bearing area (square inches)

- L = load on bearing (LBS)

- V = velocity of the shaft (surface feet/minute = SFM)

- RPM = Revolutions per minute of shaft

- D = shaft diameter (inches)

- l = length of bushing through the bore (inches)

Bearing Installation

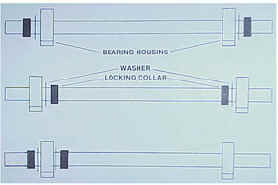

Proper installation MUST follow one of the above three diagrams unless used in conjunction with a rolling-element bearing.