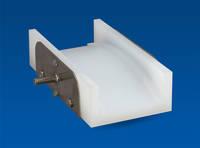

Snapidle™ Chain Tensioners

- Free-floating

- Any size or attitude

- Tames reversing drives

Click on the photos below for a larger view.

1

| Standard Snapidle Dimensions

Inches |

|||||||

|

S i n g l e

P i n |

SI # |

A |

B |

C |

D |

E |

|

| 40 | 0.62 | 1.50 | 2.68 | 3.00 | 1.036 | ||

| 50 | 0.75 | 1.69 | 2.87 | 3.50 | 1.036 | ||

| 60 | 1.06 | 1.94 | 3.12 | 4.00 | 1.036 | ||

| 80 | 1.31 | 2.32 | 3.75 | 4.50 | 1.036 | ||

| 100 | 1.56 | 2.65 | 4.06 | 5.00 | 1.388 | ||

| 120 | 2.07 | 3.40 | 4.81 | 5.50 | 1.638 | ||

|

D u a l

P i n |

140 | 2.07 | 3.40 | 4.81 | 5.50 | 1.638 | |

| 160 | 2.44 | 3.84 | 5.25 | 6.50 | 1.638 | ||

| 180 | 2.63 | 4.18 | 5.56 | 7.00 | 1.649 | ||

| 200 | 2.91 | 4.65 | 6.00 | 7.50 | 2.70 | ||

| 240 | 4.19 | 6.02 | 7.37 | 8.00 | 2.70 | ||

| *** | |||||||

*** #300, #400, #500 and #600 are assembled to the width of the chain ordered. For this reason, specific dimensional information and weights will be supplied on request by M.I.C.

Download Our Product Catalog